Sealing and renovation of joints

When it comes to joints, we basically distinguish between 2 tasks: the execution of joints that have to absorb movement = expansion joints and the execution of joints and cracks that are not designed to compensate for movement.

In both cases sealing and renovation must be carefully planned to ensure a sealed and safe solution. The technical solutions for joints that have to absorb movements are particularly demanding.

Even if expansion joints are to be avoided in chemically contaminated areas, this is not feasible for every project from a structural engineering point of view. They can be found in all areas of industry and serve in their various forms to catch movements between different components.

If expansion joints are exposed to aggressive media that are hazardous to water, the expansion joint materials and expansion joint design must meet high requirements in terms of sealing and chemical resistance. Therefore, expansion joints must be executed with special technical attention.

Expansion joint systems must have a high degree of flexibility or elasticity to accommodate the movements that occur between different components.

Depending on whether they are driven over, special constructional details must be taken into account in the design.

The choice of expansion joint system suitable for the specific project is selected on the basis of the chemical, thermal and mechanical load.

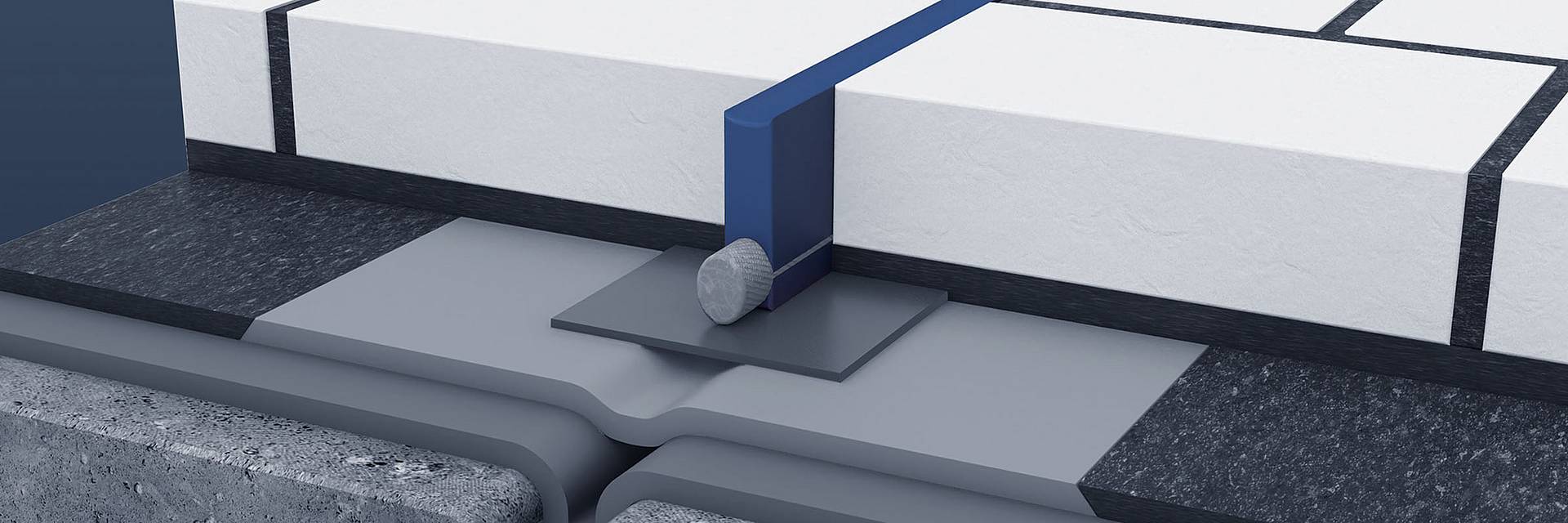

The spectrum of expansion joint systems available ranges from permanently elastic jointing compounds and joint tapes to tested PE foam profiles with national technical approval.

With our approved jointing system Steulerplast PE we can offer a technical solution that enables, for example, a highly chemically resistant design, which is also passable by vehicles.

If a joint is not clearly identifiable or marked as an expansion joint, it is primarily important to clearly identify the cause of the corresponding joint. In this context, cracks are often also referred to as joints.

From a structural engineering point of view, intended and expected construction joints and shrinkage cracks can normally be repaired without problems. They are cut and cleaned, mechanically prepared to achieve sufficient adhesive tensile strength and then filled.

However, older buildings in particular often show joints and cracks, the cause of which is not so easy to clarify. Here, it is not enough to simply choose a permanently elastic version, for example, in order to feel that you are on the safe side.

There could be a static cause, for example. Think of a basin that is emptied and filled every now and then. Here, this stress must be taken into account statically for the supporting structure. Perhaps the filling volume has also changed over the period of use, but the construction has not been adapted. Careful clarification of the causes is required in this case in order to find a technically suitable solution for the repair.

Our possibilities are almost unlimited. Contact us. Together with you, we will find the exact solution for your project.