Acid resistant tile linings

High-quality tile linings from Steuler are created from acid-resistant ceramic tiles and bricks as well as carbon materials.

In combination with water glass and synthetic resin-based application and jointing mortars, they provide lasting protection against aggressive media.

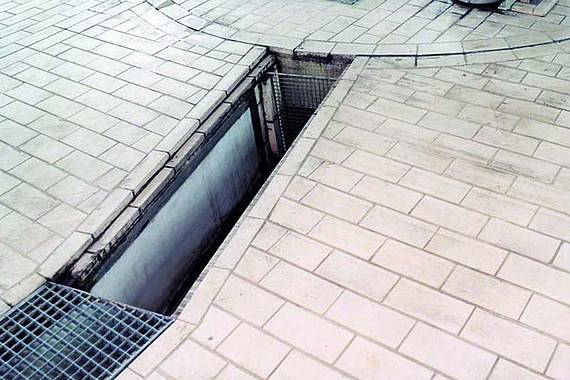

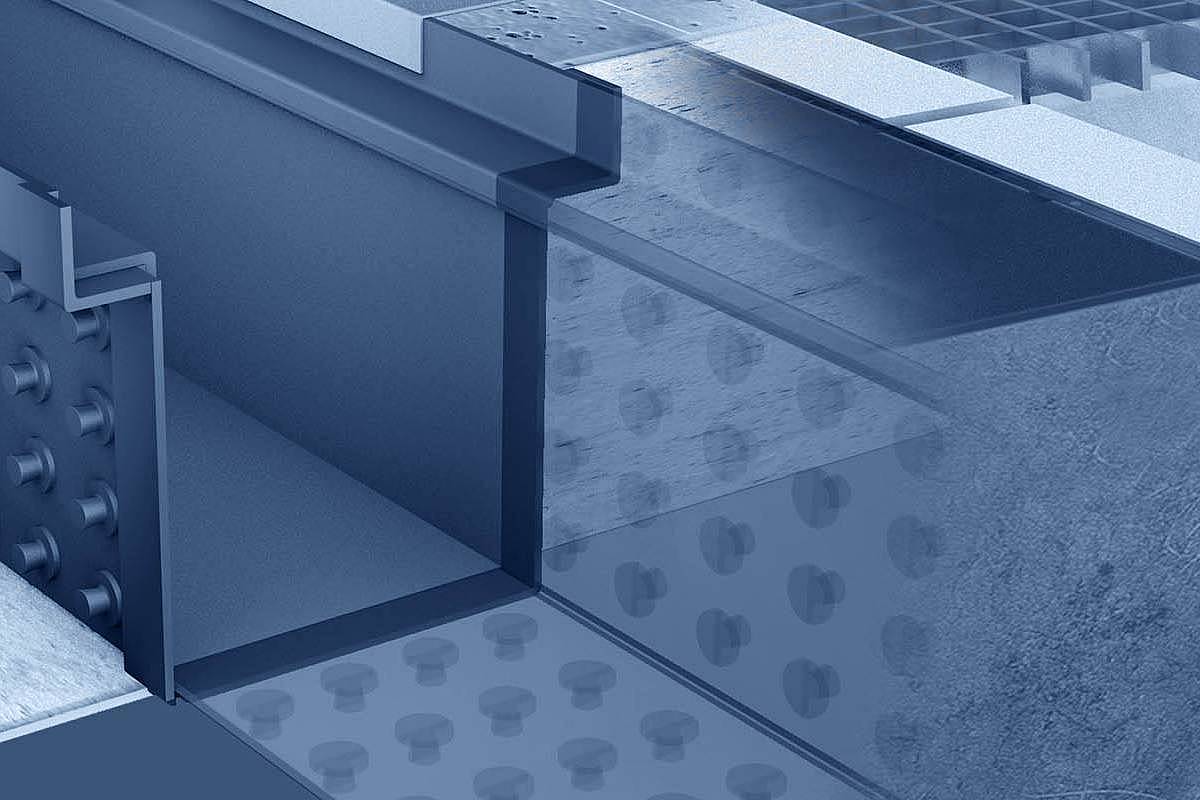

Steuler ceramic tile lining have low open porosity and high chemical resistance. The high mechanical strength and good abrasion resistance when used on floors or areas with abrasive loads provide reliable protection of the sealing layers. Added to this is the professional execution of construction details, such as the connection to stainless steel fixtures, trenches, drains or wall connections.

Acid-resistant tile linings from Steuler are available in numerous standard and special formats.

Heavy loads due to vehicles, abrasive stress in production or during maintenance work - Steuler tile linings can withstand even extreme stresses and loads. The high slip resistance of these areas improves operational processes and increases occupational safety.

Individual selection of materials and formats

- Normal bricks, shaped bricks and special formats in various brick qualities (acid resistant ceramics, graphite and carbon bricks)

- Sealing layers based on polyurethane, epoxy resin, polyester resin (unsaturated), vinyl ester resin, furan resin; special formulations; rubber linings; thermoplastics

- Synthetic resin mortars based on furan resin, phenolic resin, polyester resin (unsaturated), vinyl ester resin, various water glass mortars; special formulations

Very important:

For various combinations of chemically resistant sealing and tile lining, we have general construction technique permits from the DIBt, including for the systems ALKADUR HR-LF Protect 2, FURADUR Laminate A93 Protect, OXYDUR UP 82 Protect and OXYDUR VEL SR Protect 2.

Tile lining in the pharmaceutical and food industry

In companies that manufacture pharmaceutical products or foods, the floor is always a functional component of complex technical systems. Legal requirements for occupational safety and hygiene must be met, as well as GMP guidelines and technical production requirements. Against high loads, ceramic linings made of tiles or hexagonal tiles are the first choice. Two points are particularly important for professional execution: application and jointing must be done with resistant materials. Underneath the ceramic, a durable sealing layer must protect the structural substrate.

This permanently prevents media from entering the substrate and damaging the building substance. Where there are no damaged areas, there are no hygienic problem zones.