Different bleaching media are used, but in any case they are so aggressive that a safe and durable sealing and lining is required. Therefore, bleaching towers must be designed with special technical attention.

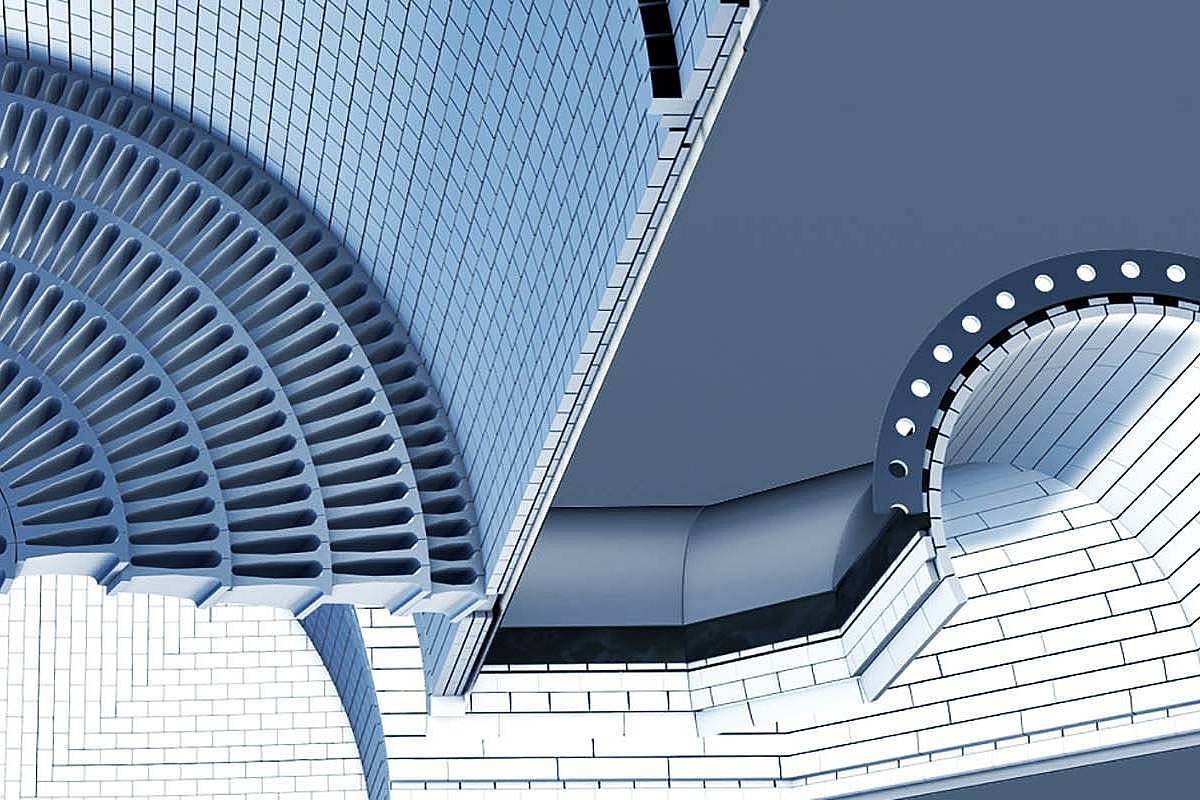

Bleaching towers are at the heart of the pulp refining process. The bleaching towers, which are mainly made of steel, are lined to protect them against corrosion. The lining is in direct contact with the base materials later processed into pure white paper products. In addition to the protective function for the steel, this lining must be designed in such a way that it does not introduce any impurities into the processed pulp.

As a further stress criterion, the mechanical stress due to the flow of the pulp must be taken into account. The fiberglass reinforced sealing system (laminate coating) must therefore be proteced by an acid-resistant lining. Here we use specially shaped bricks and overflow bricks to be able to realize the best technical solution.

As a rule, bleaching towers are insulated on the outside to keep energy losses as low as possible. Since the substrate (steel) and the lining system behave differently physically, damage can occur if these influences are not taken into account in the design. We also offer technically optimized, constructive solutions for this.

Every project takes a slightly different form. Based on many years of experience and corresponding know-how, we will work with you to find the right, individually tailored solution for your project. Do not hesitate to contact us.